Accessories for Oil Transformers

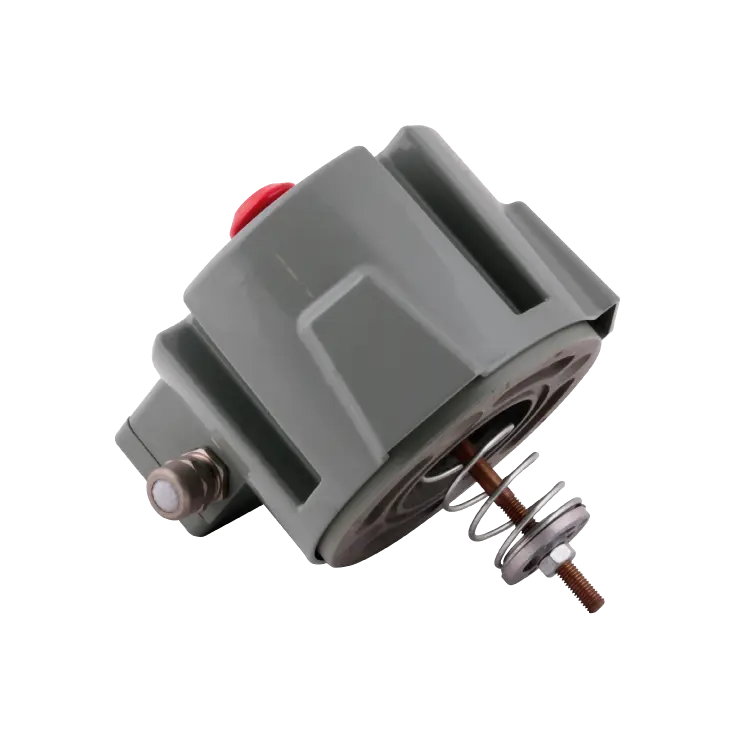

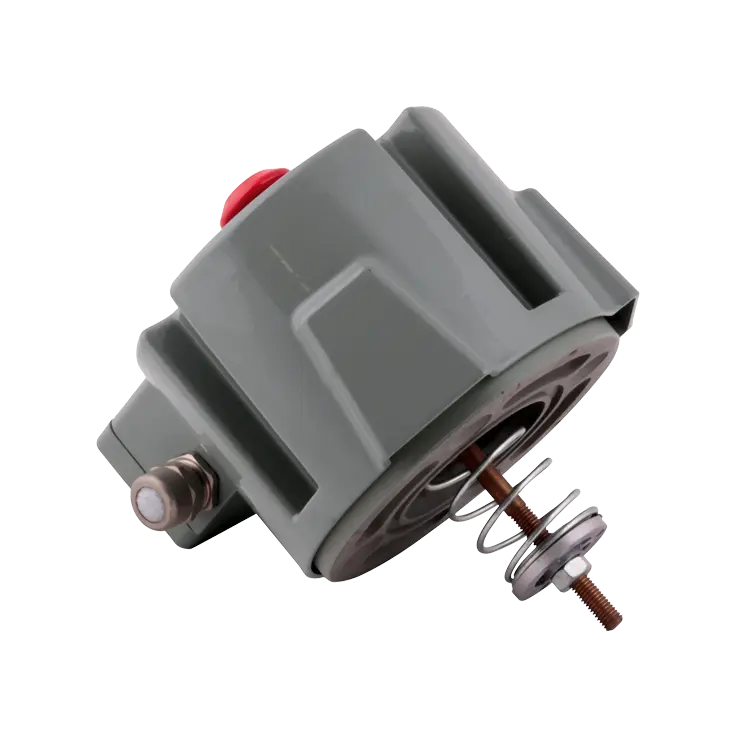

Pressure Safety Valves Type T

Pressure Safety Valves are used to prevent the rapid build-up of pressure within the transformer tank that might cause an explosion hazard. They are designed to operate and discharge any pressure greater than their set value to the atmosphere.

These pressure safety valves are available in two sizes:

- T-50

- T-80

Do you have questions about our product, would you like personal advice, or do you want to place an order? Our team is happy to assist you with help and guidance! Quality and expertise from a single source!

Construction

This valve type consists of a flanged body and a corrosion proof aluminum alloy disc/sleeve arrangement. The disc/sleeve is attached to a central rod which is spring loaded. The valve has two gaskets, one is of a special design that is fully compressed by the disc under normally closed conditions, and the other is a lateral o-ring that operates on the sleeve part of the disc. Valves are designed such that the operating components are mounted inside the valve body. Hence the mechanism is protected from external influences. They have an additional outside cover made of aluminum which further increases the protection against the atmospheric conditions. They have also a visual operation indicator on the top section. The external surfaces are protected against all climatic conditions. Steel parts are stainless or nickel plated steel and those parts in aluminum alloy are additionally protected with two layers of special paint. Hence the valves are suitable for operating in temperatures between -25°C and +100°C. Valves can be calibrated to operate any pressure between 0.3 and 0.7 bar. An optional switch is available which is operated by the same rod as the visual indicator and can be used to electrically trigger a warning locally or remotely. The switch is protected by a watertight box, and remains pressed until the visual indicator resets manually. The switch characteristics are as follows: AC 11 220 / 380 V ~ 5 / 3 A

Operation

When the internal pressure pushes the disc and starts to compress the spring, the specially designed gasket maintains the seal for up to 2 mm of movement and the lateral o-ring also maintains the seal. Increasing pressure causes the special gasket to break seal but the lateral o-ring seal remains. At this stage the overall area of the disc/sleeve containing the pressure has been increased. Further pressure causes the valve to open fully and discharge instantly. When the pressure is equalized the spring action closes the valve, first effecting the seal via lateral o-ring and then the special gasket. When the valve operates, it also causes a central rod to protrude from the protective casing giving an immediate visual indication.

Installation

Our valves are available in 2 sizes according to their discharge areas and are selected according to the transformer oil volume as follows:

Transformer Oil Volume (dm³):

- Up to 3000 T-50

- Up to 9000 T-80

For higher volumes of oil, two or more valves should be used. It is recomended to use two or more valves of smaller section than one valve of large section. Valves can be positioned at critical points above a winding where the pressure effect is more acute during a short circuit. In order to ensure correct operation of the valve, any trapped air should be bled via the screw provided so that the oil is in direct contact with the disc.

Suitable for this

Quality and expertise from a single source

For over 60 years, we have been successfully operating in the market as an owner-managed company. We combine tradition with innovation and stand for fairness and the highest quality. Founded more than six decades ago, we have continuously developed and established a recognized name.

Learn more about the company